Crude vegetable oils, extracted from seeds or kernels through mechanical or solvent extraction, contain various impurities and undesirable components. These include phosphatides, free fatty acids (FFAs), colour pigments, odoriferous compounds, oxidation products, metal contaminants and traces of pesticides or heavy metals.

Refining removes these unwanted elements to produce edible oils that meet stringent food safety and quality standards. The refining process varies based on the raw material's quality and the desired end-product specifications, ensuring minimal loss of valuable components while achieving optimal stability, taste and nutritional value.

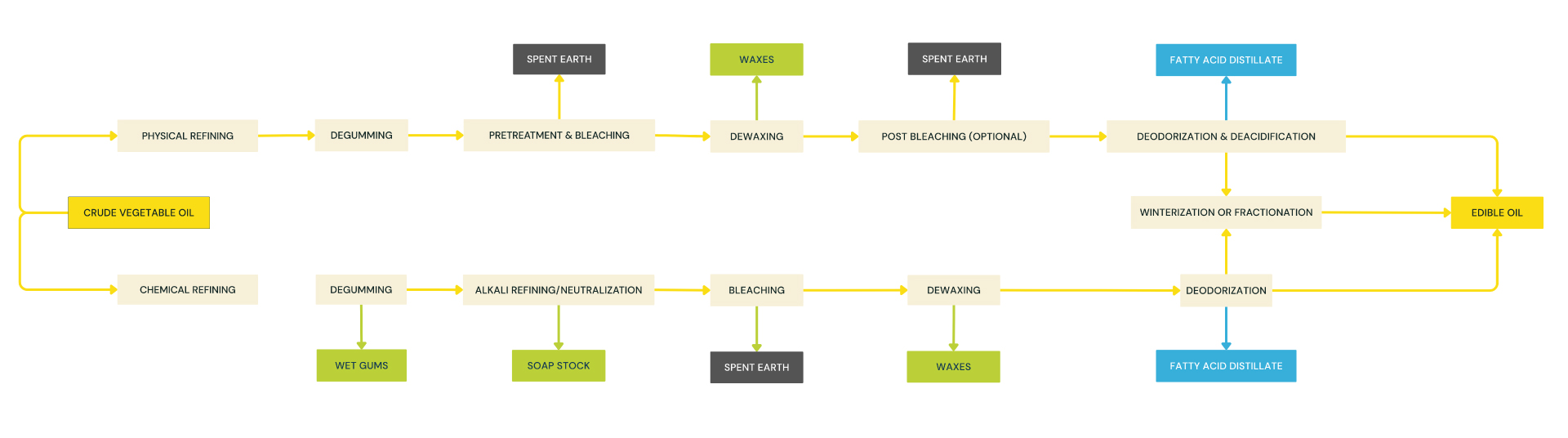

Vegetable oils are refined using one of three primary methods:

Kumar's Oils & Fats refining process

Refining crude oils into high-quality edible oils involves a carefully engineered sequence of steps, each tailored to remove specific impurities while preserving desirable characteristics.

Degumming, the first step in the process, removes phosphatides and hydratable gums, with water, acid or enzymatic degumming selected based on the nature of the crude oil. Neutralisation, or alkali refining, distinguishes chemical refining from physical refining by neutralising free fatty acids with caustic soda to form soapstock, which is then separated by centrifugation. Bleaching, common to both methods, uses activated earth to adsorb colour pigments, residual phosphorous, soap traces, peroxides and metal contaminants. Dewaxing follows, removing high-melting non-triglyceride compounds through crystallisation and filtration to enhance oil clarity and cold stability.

An optional post-bleaching step further fine-tunes colour and reduces contaminants. Deodorisation, a critical phase, removes odorous and volatile compounds via steam distillation while improving colour through heat bleaching. In physical refining, deacidification and deodorisation occur together, stripping out FFAs and volatiles to produce a clean, low-acid oil. Finally, winterisation or fractionation separates high-melting triglycerides that cause cloudiness at low temperatures, ensuring bright clarity and stable performance in cold conditions.

Advantages of Kumar’s oil refining process

At Kumar, we engineer sustainable, high-efficiency refining systems that ensure exceptional performance, product purity, and process optimisation. When it comes to refining oils and fats, we've got what it takes for you to thrive.

Applications

Kumar's refining plants meet the highest purity, nutritional value and quality standards for a wide range of crude oils.

Solutions for oils and fats refining

Our oils and fats refining processes feature Kumar and CPM-Crown-designed systems that transform crude oils into safe, high-purity edible products. Using chemical, physical or hybrid methods, these systems remove free fatty acids, gums, pigments and odour compounds while preserving stability and nutritional value. Each stage is engineered to maximize yield and ensure compliance with the strictest food standards. By uniting CPM-Crown's global expertise with Kumar's engineering strength, we deliver refining solutions that are efficient, reliable and built for consistent quality.

Our services

We help minimise downtime and keep your operations running smoothly through a combination of high-quality components, advanced technology and expert on-demand support. Our service standards ensure your plant performs at its best, day in and day out.

Audits

Detailed performance reports to assist with process changes related to output, energy consumption, spares, inventory and plant upgrades.

Project EPC

Full or partial turnkey management and execution of the project from cost projections and modelling to installation and commissioning.

Spares

Spare parts as required to maximize uptime and ensure the longevity of your investment.