Oil-bearing seeds such as soybeans, sunflowers, cotton, groundnuts, mustard, sheanuts, canola, rapeseed, and rice bran must be carefully prepared before extraction. Proper preparation ensures maximum oil recovery and protects downstream equipment. Depending on protein requirements, seeds can also be partially or fully dehulled.

Kumar's integrated oilseed preparation systems are designed to maximise oil yield, safeguard product quality and reduce operating costs — engineered to perform reliably across all seed types and scales of operation.

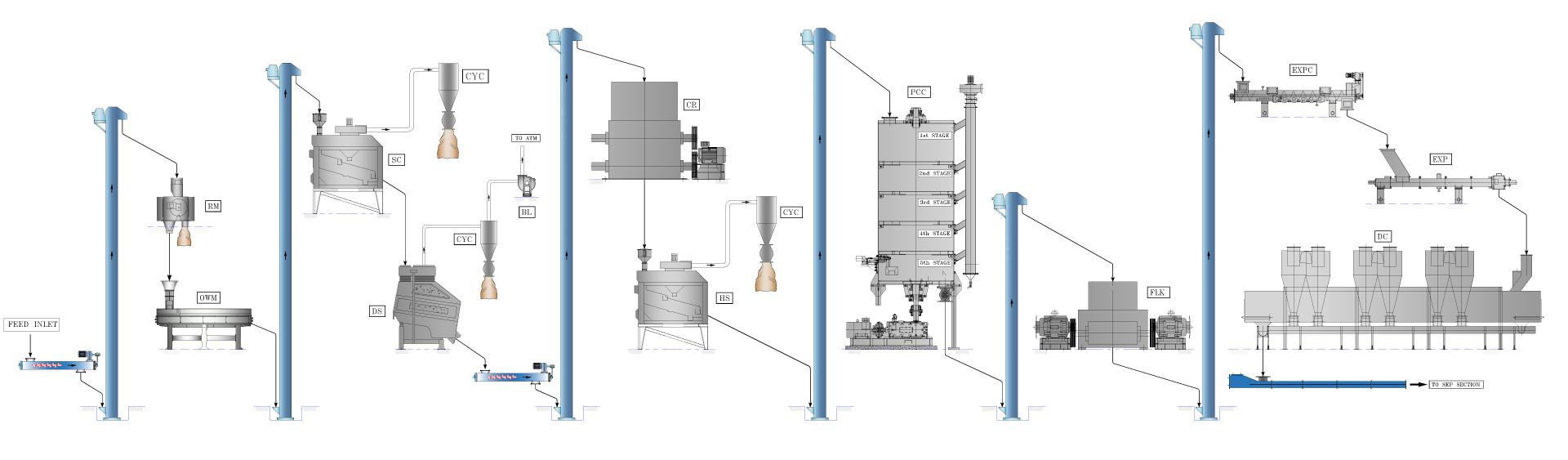

Oilseed preparation involves a carefully engineered sequence of mechanical operations, each designed to condition seeds for efficient extraction.

Advantages of Kumar's oilseed preparation process

Kumar’s preparation systems combine precision engineering with process know-how to deliver maximum oil recovery, reduced processing losses and consistent product quality. Each plant is optimised for throughput, energy efficiency and long-term reliability — because when it comes to oilseed preparation, we’ve got what it takes for you to thrive.

Applications

Kumar's preparation plants are versatile and adaptable for various oilseeds including soybean, sunflower, cotton, rapeseed, mustard, groundnut, sesame, castor, sheanut and rice bran.

Solutions for oilseed preparation

Our oilseed preparation processes feature Kumar and CPM-Crown-designed equipment where each stage is engineered to maximize oil recovery, protect downstream equipment and improve meal quality. These solutions ensure consistent results across diverse feedstocks and are adaptable to a range of oilseeds. Combining CPM-Crown's proven technologies with Kumar's local expertise and engineering strength allows us to deliver preparation systems that improve efficiency, reduce losses and secure long-term reliability.

Our services

We help minimise downtime and keep your operations running smoothly through a combination of high-quality components, advanced technology and expert on-demand support. Our service standards ensure your plant performs at its best, day in and day out.

Audits

Detailed performance reports to assist with process changes related to output, energy consumption, spares, inventory and plant upgrades.

Project EPC

Full or partial turnkey management and execution of the project from cost projections and modelling to installation and commissioning.

Spares

Spare parts as required to maximize uptime and ensure the longevity of your investment.