Solvent extraction is the most efficient method for recovering oil from oilseeds and press cakes, achieving yields above 95%. It is the industry standard for processing large volumes of material with minimal residual oil.

In this process, prepared oilseed material is subjected to counter-current extraction with hexane, which dissolves the oil to form miscella. The miscella is separated, distilled and recycled, while the de-oiled meal passes through a desolventiser toaster for solvent recovery and conditioning. Efficient distillation and condensation systems ensure solvent recovery rates of over 95%, making the process economical, reliable and sustainable for high-capacity plants.

Kumar's solvent extraction plants are engineered with specially designed wedge wire screens and optimised miscella flow systems for maximum oil recovery. Desolventiser toasters ensure safe and efficient meal conditioning while achieving high solvent recovery. Distillation units, economisers and hydroclones are integrated for energy savings, consistent operation and reduced maintenance. Robust construction, automation-ready systems and solvent recirculation capabilities make these plants efficient, safe and cost-effective.

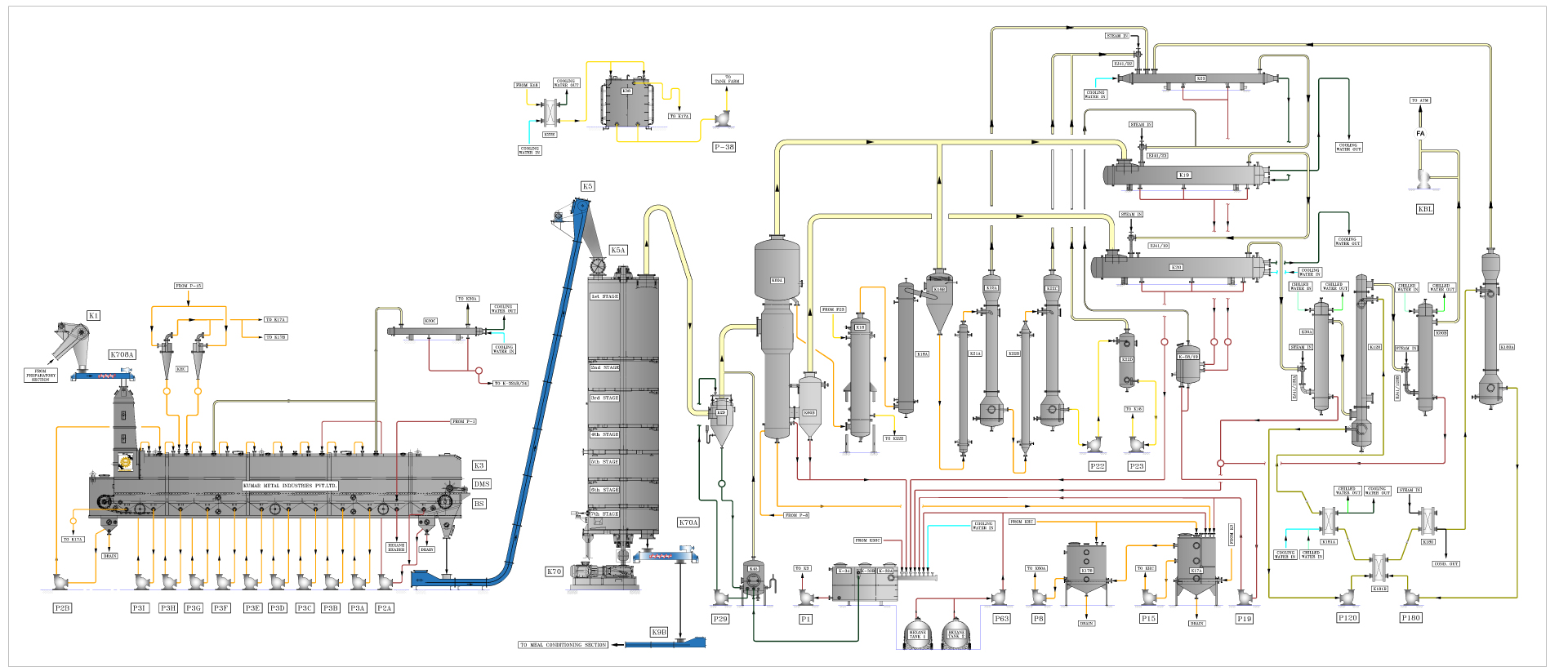

Plant process flow diagram

Solutions for solvent extraction

Our solvent extraction processes feature Kumar and CPM-Crown-designed systems that deliver high oil recovery with minimal residual content in the meal. Using counter-current solvent flow, vapour recovery, and desolventizing technology, these systems achieve yields of over 95% while reducing energy use and solvent loss. Our extraction solutions are adaptable to diverse oilseeds and capacities. They ensure consistent performance at scale that is proven, economical, and built for long-term reliability.

Our services

We help minimise downtime and keep your operations running smoothly through a combination of high-quality components, advanced technology and expert on-demand support. Our service standards ensure your plant performs at its best, day in and day out.

Audits

Detailed performance reports to assist with process changes related to output, energy consumption, spares, inventory and plant upgrades.

Project EPC

Full or partial turnkey management and execution of the project from cost projections and modelling to installation and commissioning.

Spares

Spare parts as required to maximize uptime and ensure the longevity of your investment.