Kumar’s material handling systems offer robust, high-capacity transport solutions for oilseeds, meals, and bulk materials, built for durability, modularity, and low maintenance.

Built to move. Engineered to last.

Description

Kumar’s range of Elevators and Conveyors is engineered for efficient, continuous material handling across oilseed processing and refining plants. These systems are available in a variety of capacities and materials of construction, and are designed for easy onsite assembly and long service life. Whether you’re lifting, conveying, or transferring solid materials, Kumar’s Bucket Elevator, Screw Conveyor, and Chain Conveyor systems ensure smooth, dust-free, and reliable movement of feedstock and processed product.

Each solution is built to handle high wear and load conditions with minimal maintenance and maximum uptime.

1. Bucket Elevator

A vertical conveying system ideal for lifting granular and free-flowing materials.

Features:

- Chain or belt variants available

- Special hardened steel chains and seamless buckets for high wear resistance

- Locking mechanism to prevent reverse rotation

- Quick assembly design for faster installation

Capacities (60% filling):

| Bucket Size | Capacity |

|---|---|

| 6” x 4” x 3.25” | 6.4 m³/hr |

| 8” x 5.25” x 4.5” | 15.1 m³/hr |

| 10” x 6” x 5” | 27.6 m³/hr |

| 12” x 6” x 4” | 34.5 m³/hr |

| 14” x 7” x 6” | 6 m³/hr |

2. Chain Conveyor

Designed for horizontal material transport with minimal breakage and high strength.

Features:

- Heavy-duty fabricated chain with hardened links

- Bottom lined with abrasion-resistant material

- Modular sizes for flexible plant integration

- Low-maintenance design for high-throughput applications

Capacities

| Redler Size | Capacity |

|---|---|

| 200 mm | 16.8 m³/hr |

| 250 mm | 21 m³/hr |

| 300 mm | 32.9 m³/hr |

| 350 mm | 38.3 m³/hr |

| 400 mm | 43.8 m³/hr |

| 500 mm | 54 m³/hr |

3. Screw Conveyor

Suitable for controlled, enclosed conveying of powdered or granular materials.

Features:

- Semi-Teflon hanger bearings for reduced lubrication needs

- Minimal flow obstruction for smooth transfer

- Various screw diameters and configurations

- Ideal for feed, meal, and waste handling

Capacities (40% filling):

| Screw Diameter | Capacity |

|---|---|

| 150 mm | 3.8 m³/hr |

| 200 mm | 9 m³/hr |

| 230 mm | 13.6 m³/hr |

| 250 mm | 17.6 m³/hr |

| 300 mm | 30.5 m³/hr |

| 350 mm | 48.5 m³/hr |

Download brochure

"*" indicates required fields

Request a call

"*" indicates required fields

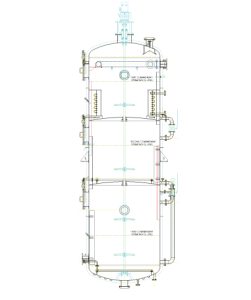

Refining portfolio

Our oil refining processes feature Kumar and Crown designed equipment including bleachers, deodorizers, filters and vacuum systems precision engineered to the highest industry standards, to deliver superior product output. All equipment is seamlessly integrated into turnkey refining plants designed and engineered by Kumar for maximum performance, reliability, and efficiency.

Our services

We help minimize downtime and keep your operations running smoothly through a combination of high-quality components, advanced technology and expert on-demand support. Our service standards ensure your plant performs at its best, day in and day out.

Audits

Detailed performance reports to assist with process changes related to output, energy consumption, spares, inventory and plant upgrades.

Project EPCM

Full or partial turnkey management and execution of the project from cost projections and modelling to installation and commissioning.

Spares

Spare parts as required to maximize uptime and ensure the longevity of your investment.