Livestock and poultry feed must deliver consistent quality, balanced nutrition, and efficient performance. Proper milling and pelleting transform raw ingredients into feed that improves digestibility, reduces waste, and supports healthy growth.

Kumar’s feed milling and pelleting systems cover every stage — from raw material grinding to pellet cooling and packing. With automation-ready designs and modular scalability, our plants help commercial and integrated farms achieve optimal feed conversion, uniform nutrient distribution, and long-term efficiency.

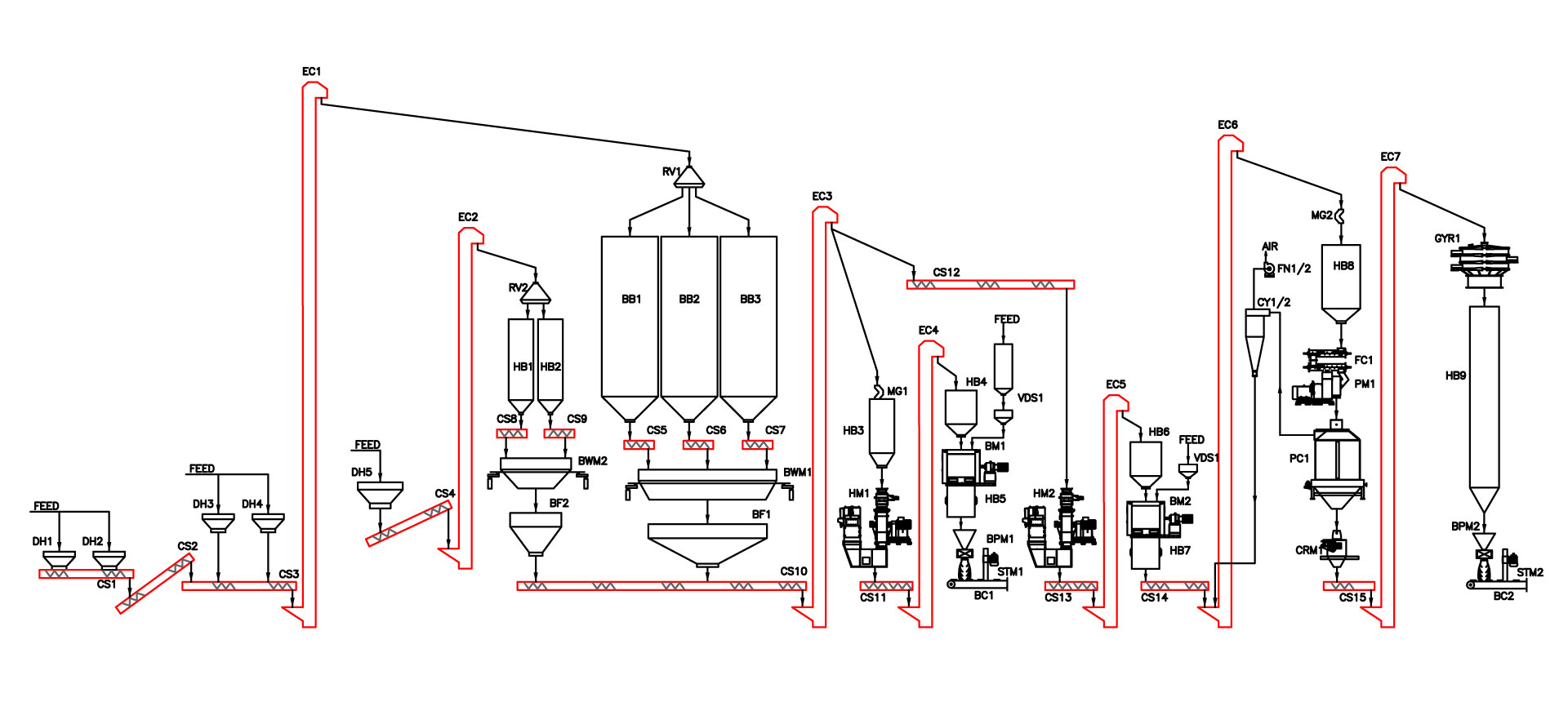

Milling and pelleting involve a precise sequence of size reduction, mixing, conditioning, pelleting, and cooling steps — engineered for efficiency, hygiene, and consistent quality.

Kumar’s milling process

Pelletization improves feed conversion efficiency with digestible, palatable pellets. Nutrients are evenly distributed, heat and pressure ensure microbial safety, and compact pellets reduce spillage, dust, and sorting losses. Kumar’s systems are built for efficiency and cleaner operations and support automated feeding systems across species and formulations. They utilize input materials like maize, soybean meal, rice bran, broken grains, wheat bran, oil cake, additives, premixes, vitamins and minerals to generate nutritious animal feed.

Solutions for feed milling

Kumar provides turnkey feed milling plants with equipment, including hammer mills, mixers, conditioners, pelletizers, coolers, crumblers, rotary sieves, dust collectors, automated packing systems, and PLC-based control panels. Each system is engineered for precision, reliability, and scalable performance — helping producers deliver consistent, high-quality feed with maximum efficiency.

GET A QUOTEOur services

We help minimise downtime and keep your operations running smoothly through a combination of high-quality components, advanced technology and expert on-demand support. Our service standards ensure your plant performs at its best, day in and day out.

Audits

Detailed performance reports to assist with process changes related to output, energy consumption, spares, inventory and plant upgrades.

Project EPC

Full or partial turnkey management and execution of the project from cost projections and modelling to installation and commissioning.

Spares

Spare parts as required to maximize uptime and ensure the longevity of your investment.